Speed at Kide is an ongoing commitment. Speed of cold room assembly and, it goes without saying, speed of delivery.

Manufacture in 48 hoursWe manufacture your cold room with its corresponding refrigeration equipment in only 48 hours.

Unifying the panel shapes, the panels are interchangeable with each other. This simplifies the assembly of the camera.

Easy to expand in all directionsIt is really easy to expand the size of a pre-installed cold room in both directions. A minimum amount of panel references provides a maximum number of modular cold rooms.

By standardizing the panel shapes, the panels are packaged in a more compact form, which facilitates their transport and handling. In addition, by reducing the number of references required, you can optimize the stocks available in your warehouse.

Fully interchangeable panelsAny panel can be used for a wall or ceiling, as they all incorporate an exclusive system whereby can be assembled in any position.

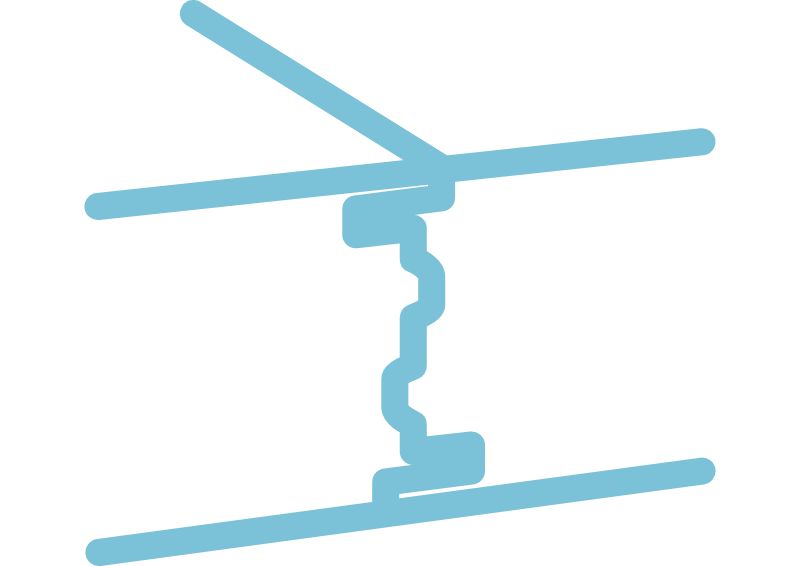

Jointing system

Jointing system

The eccentric hook joint system guarantees the tightness of the joints of both panels. It includes a hexagonal wrench KEY to facilitate the connection of the hooks.

PIR foam chambers

PIR foam chambers

The UNIVERSAL cold room is composed of modular panels injected with high-density rigid polyisocyanurate foam, with a range of thicknesses to suit different insulation needs.

Kide system

Kide system

The advantages of our hook fastening system also translate into faster and easier assembly compared to conventional systems.

The airtightness of our cold rooms thanks to the eccentric hook joint system and the male-female format guarantees total insulation, reducing consumption to a minimum.